MVV Dişli Pompalarının Temel Prensipleri

|

PL8The PL8 is MVV's best-selling pump, known for its good performance and affordability. It is widely used in polyurethane applications, but its cast iron body may not be suitable for use with corrosive fluids. This pump is ideal for medium viscosity fluids and can handle working pressures of up to 80 bar, withstanding peaks of over 100 bar. It is a key component in many multi-component polyurethane mixing machines produced in Europe and around the world, and its precision is responsible for the quality of many everyday products, from the soles of hiking boots to the foam interiors of car dashboards. |

|

PL2The PL2 can be considered as the PL8 dressed up for a party: with a casing made of heat-treated martensitic stainless steel, it is able to handle mildly corrosive fluids. It features a larger shaft (16mm compared to 12mm), a bigger support plate, and centering dowels. It is considered a “general purpose” pump and is widely used for any dispensing application, mostly in 2K systems. Specific models are also available for the solventless lamination (converting) industry. |

|

PALWe like this pump a lot. Thanks to its simple yet rugged construction, it has been able to solve many of our customers problems.Thanks to the High Speed Steel base and the optional DLC coating, this pump is able to handle difficult fluids, high or low viscosity. A real problem solver.  |

|

PLBThis pump is essentially a PL2 with an added feature – O-rings between the plates for enhanced safety against fluid leakage.It can be easily mounted on a lantern and is commonly used in its magnetic-coupled version, particularly for dosing aromas in the tobacco industry. Many of our customers also use it to dose thick resins for applications in the automotive industry. In addition, its connection-on-the-back construction creates a less complex path for the fluid, avoiding two 90° bends and feeding the fluid directly into the gear chamber. This design helps reduce the chances of clogging and provides a smoother flow, making the pump easier to clean and maintain.  |

|

PL4When pumping low viscosity liquids such as solvents and additives, our standard pumps may face difficulties. To address this, we have designed a pump with gears made of a special thermoplastic material, PEEK, in addition to AISI316L stainless steel construction. This unique material, when combined with specific additives, achieves high levels of hardness, enabling us to pump fluids as low as 1 cP at pressures up to 30 bar with almost zero clearance. |

|

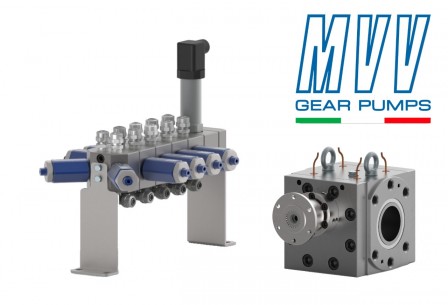

PAE booster pumpsWith the same principles of the PLE, but with different materials: the use of tool steels increases the temperature resistance. These pumps are used for melted polymers, and high-temperature polymer reactions.PAE pumps can be heated electrically or through an appropriate fluid, maintaining the process temperature. A full range of small pumps is available, from 0,3 to 30 cc/rev pumps, able to be mounted directly on 3D-Printing robot arms. |

|

PLZWe went for this shape as it's widely used on the other side of the pond. The North American market and its doosing equipment manufacturers are more than happy to have a high quality replacement for their pumps.Widely used in the personal care industry. |

|

PA6 – PA7Engineered for the textile industry, this pump has been modified through the years also thanks to our OEM customers of the hot-melt industry.Nowadays is a totally reliable, precise and sturdy gear metering pump for high temperatures and high pressures, quickly and easily available. |

|

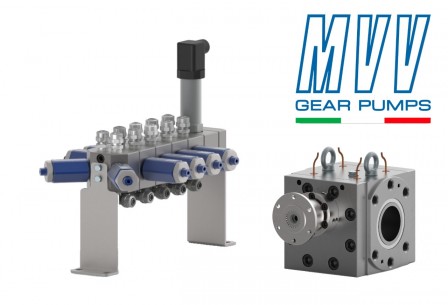

PLV e RCCThis shape is very common in the spray paint industry, mostly for automotive. This is MVV's version, available with different materials and coating options. It's suitable for slightly abrasive fluids such as pigments, colorants, carbides, oxides…The RCC color change system allows quick change from one color to another by opening and closing the corresponding pneumatic valve.  |

|

PUGThe PUG Series gear pump is the only motor-speed pump in MVV's range. This compact pump is commonly used for chemical transfer, cyclic operation, and continuous production systems, including open-ended and closed-loop applications. The PUG Series is ideal for pilot plants, vacuum systems, and metering applications. The option to choose between AISI316L and Alloy20 materials makes it suitable for use with acids and other aggressive chemicals. |