DELLMECO 2004 yılında beri lider pompa üreticisidir . Çok geniş bir yelpazede endüstriyel kullanıma uygun havalı ve elektro-mekanik çift diyaframlı pompa (AODD ve DME serileri) üretiyoruz. Aynı zamanda uluslararası olarak tanınırlığı olan ISO/TUV kalite kontrol sistemi ile desteklenen yeni fabrika tesisimizden son teknoloji ürünü tasarım ve geliştirmeler sunuyoruz.

Ürün Menşei Polonya 'dır. Eren Endüstriyel Dellmeco yetkili satıcısıdır.

|

|

|

|

|

|

Designed to succeed– temperatures up to + 120°C– pressure up to 14 bar – lubrication-free operation – low air consumption – abrasion resistance (PE, PE conductive) |

Flexible installation– BSP as standard– PN10, PN16, ANSI, NPT, JIS, RJT, split manifold configurations available – connections may rotate 180° |

Solid, compact and strong– housing machined from solid PE, PTFE as well as conductive PE and PTFE– withstands aggressive chemicals – gentle pumping action – viscous media transfer |

Perfect diaphgram– completely smooth liquid-side surface (no holes)– no metal in contact with the media – materials made to match the application |

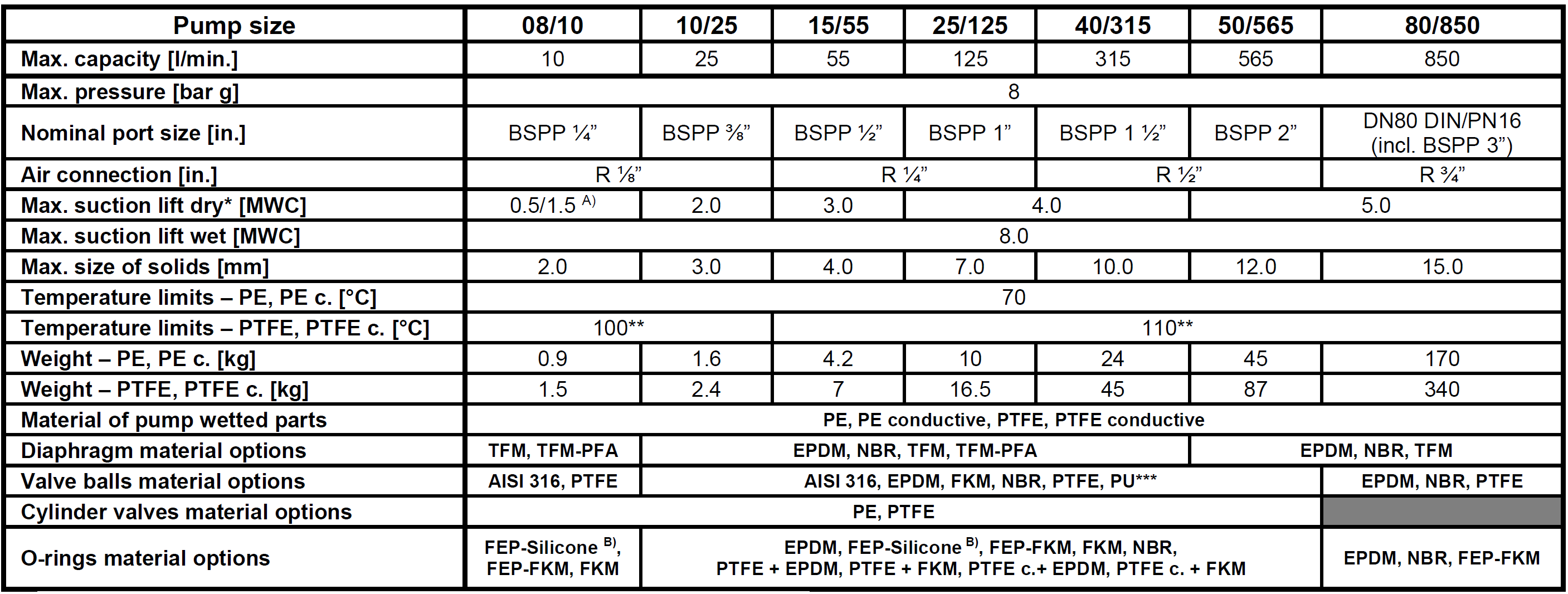

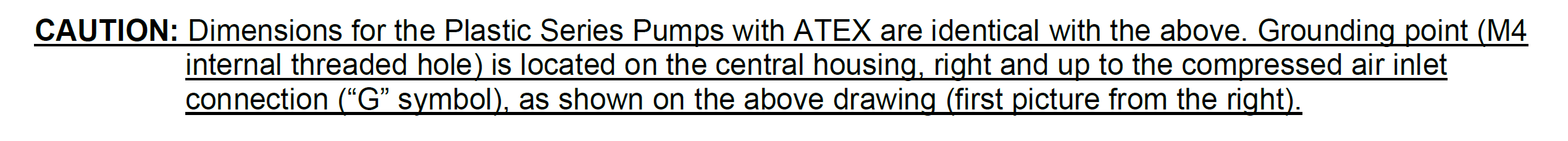

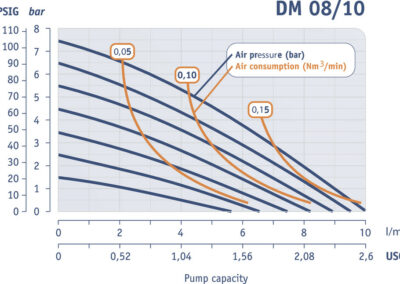

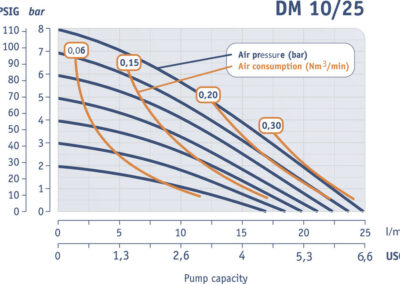

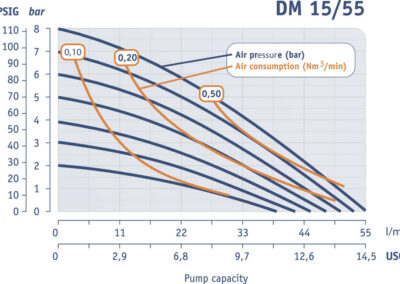

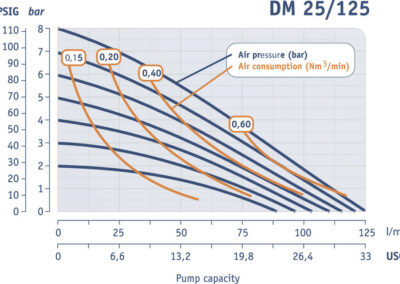

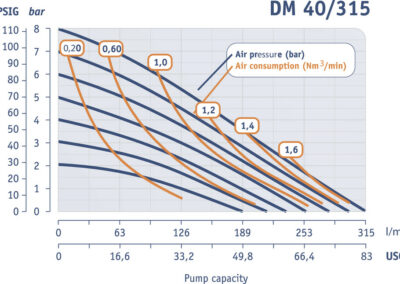

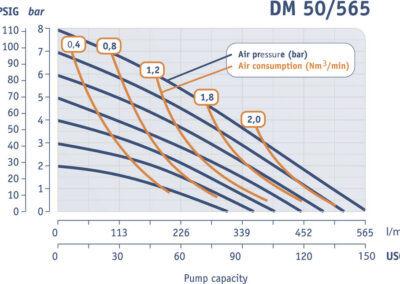

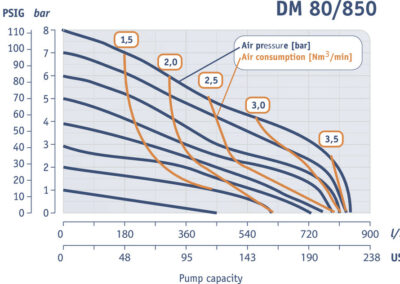

| Pump Size | DM 08/10 | DM 10/25 | DM 15/55 | DM 25/125 | DM 40/315 | DM 50/565 | DM 80/850 |

| Max. capacity [l/min.] | 10 | 25 | 55 | 125 | 315 | 565 | 850 |

| Max. pressure [bar g] | 8 | ||||||

| Nominal port size [in.] | BSPP ¼" | BSPP ?" | BSPP ½" | BSPP 1" | BSPP 1½" | BSPP 2" | DN80 DIN/PN16 (incl. BSPP 3") |

| Air connection [in.] | R?" | R¼" | R½" | R¾" | |||

| Max. suction lift dry* [MWC] | 0.5/1.5 | 2.0 | 3.0 | 4.0 | 5.0 | ||

| Max. suction lift wet* [MWC] | 8.0 | ||||||

| Max. size of solids [mm] | 2.0 | 3.0 | 4.0 | 7.0 | 10.0 | 12.0 | 15.0 |

| Temperature limits - PE, PE c. [°C] | 70 | ||||||

| Temperature limits - PTFE, PTFE c. [°C] | 100** | 110** | |||||

| Weight - PE, PE c. [kg] | 0.9 | 1.6 | 4.2 | 10 | 24 | 45 | 170 |

| Weight - PTFE, PTFE c. [kg] | 1.5 | 2.4 | 7 | 16.5 | 45 | 87 | 340 |

| Material of pump wetted parts | PE, PE conductive, PTFE, PTFE conductive | ||||||

| Diaphragm material options | TFM, TFM-PFA | EPDM, NBR, TFM, TFM-PFA | EPDM, NBR, TFM | ||||

| Valve balls material options | AISI 316, PTFE | AISI 316, EPDM, FKM, NBR, PTFE, PU*** | EPDM, NBR, PTFE | ||||

| Cylinder valves material options | PE, PTFE | ||||||

| O-rings material options | FEP-Silicone FEP-FKM, FKM | EPDM, FEP-Silicone, FEP-FKM, FKM, NBR, PTFE + EPDM, PTFE + FKM, PTFE c. + EPDM, PTFE c. + FKM | EPDM, NBR, FEP-FKM | ||||